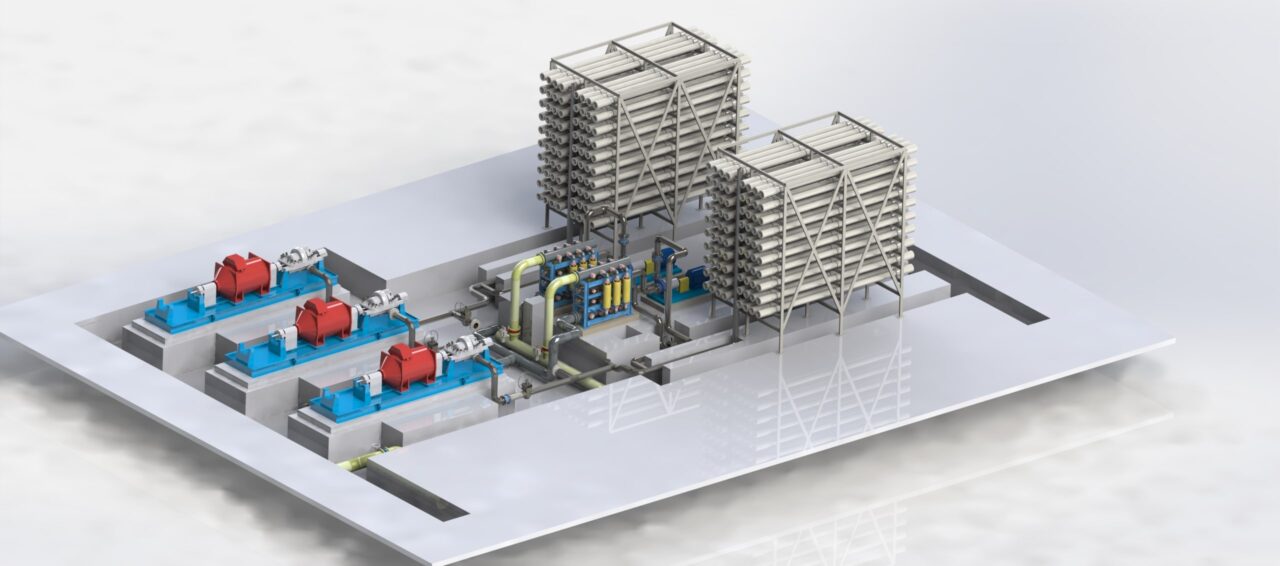

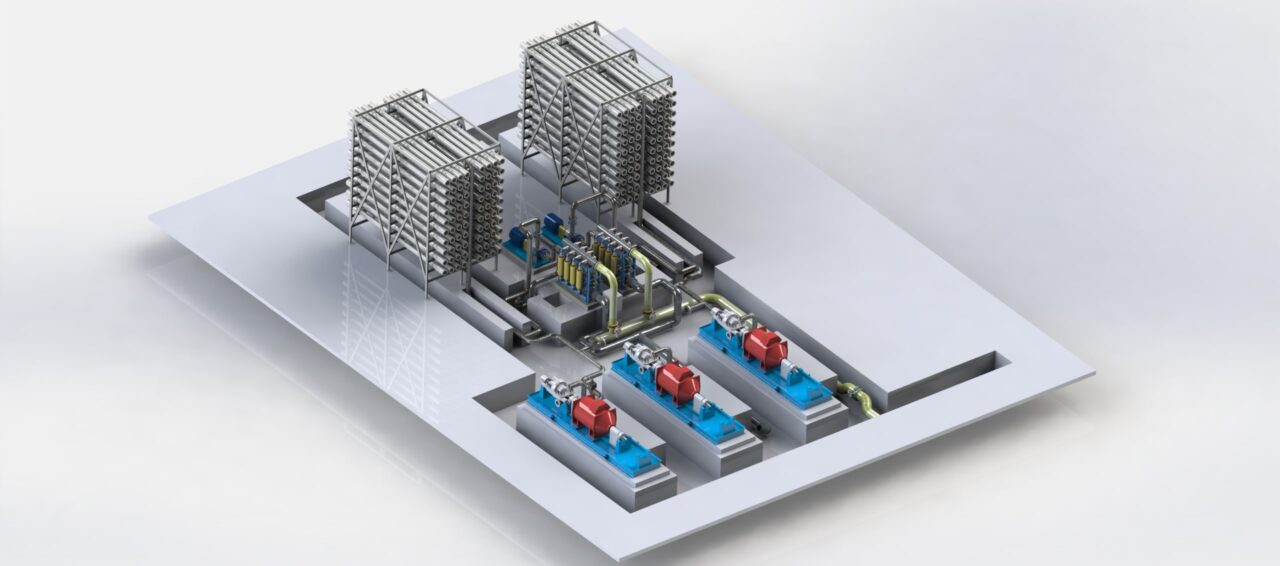

Execution of savings measures at Agragua S.A.’s EDAM.

The facility covered by this proposal is the Seawater Desalination Plant using reverse osmosis (R.O.) owned by AGRAGUA S.A., located in Bocabarranco, Gáldar, Gran Canaria.

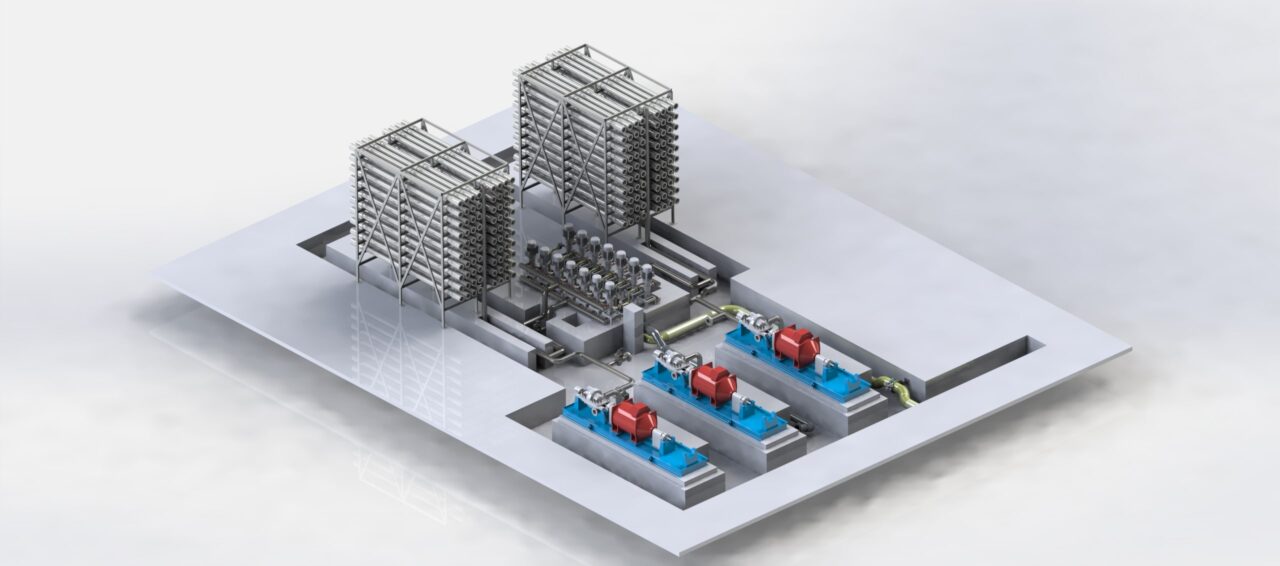

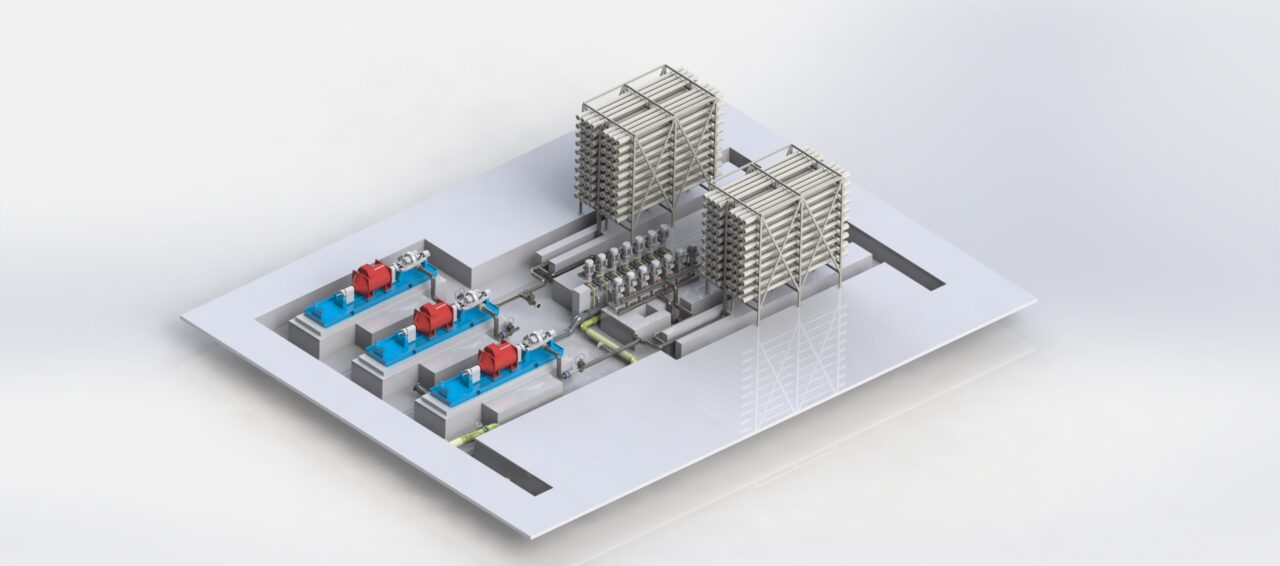

The plant currently has two independent skids, each with a nominal capacity of 5,500 m3/d, whose high-pressure pumping is supported by coupling a Pelton turbine to the electric motor.

In conventional plants, most of the hydraulic energy used in the reverse osmosis process is wasted as a pressurized brine stream discharged from the membranes. In order to reduce energy consumption during the desalination process, INEXA has considered, at the client’s request, the installation of two possible energy recovery device (ERD) options designed to prevent energy waste in the desalination process.

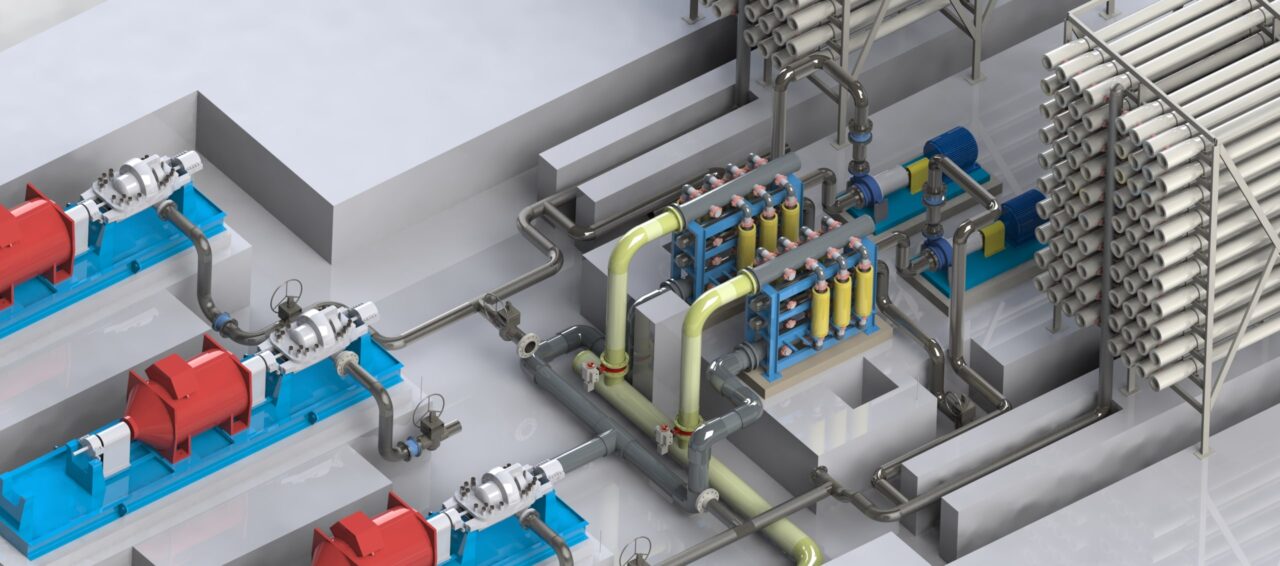

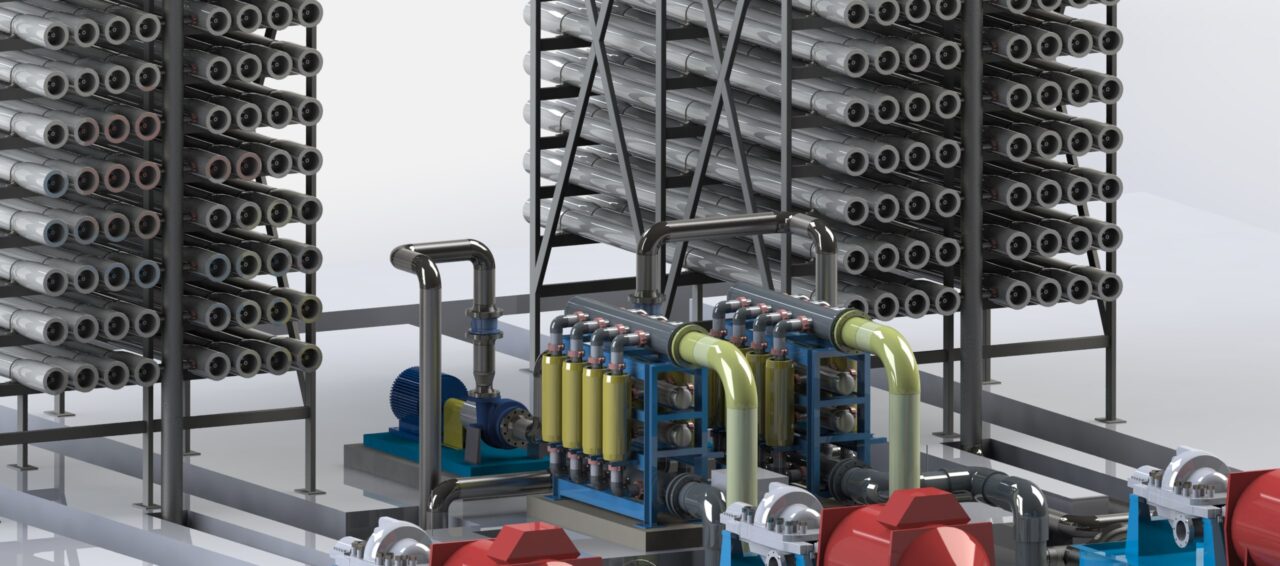

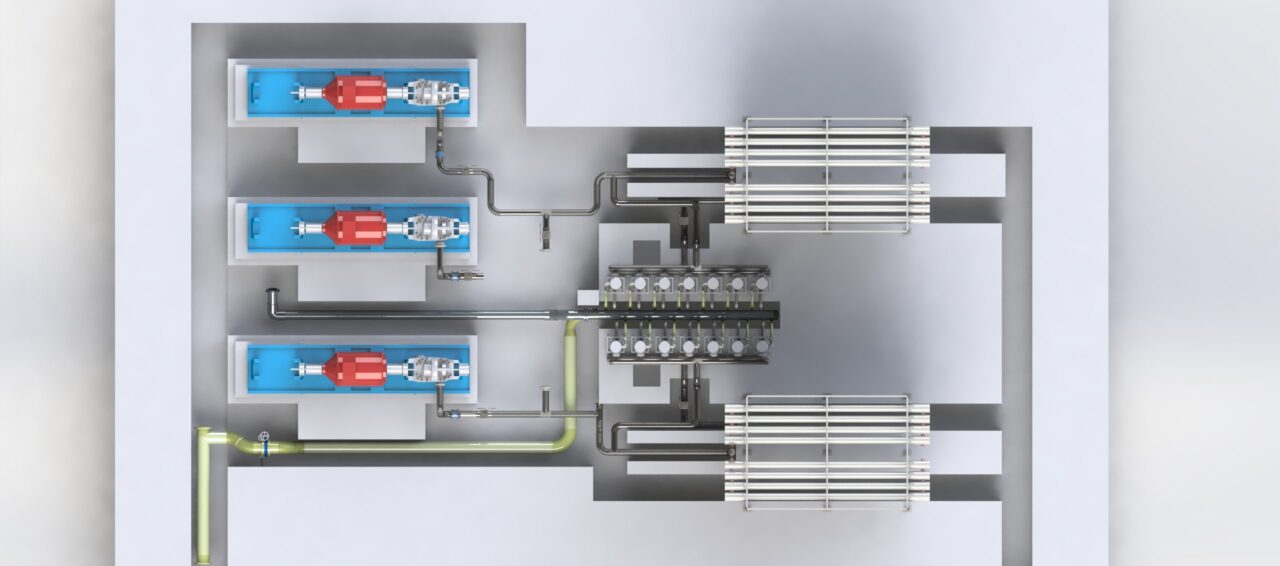

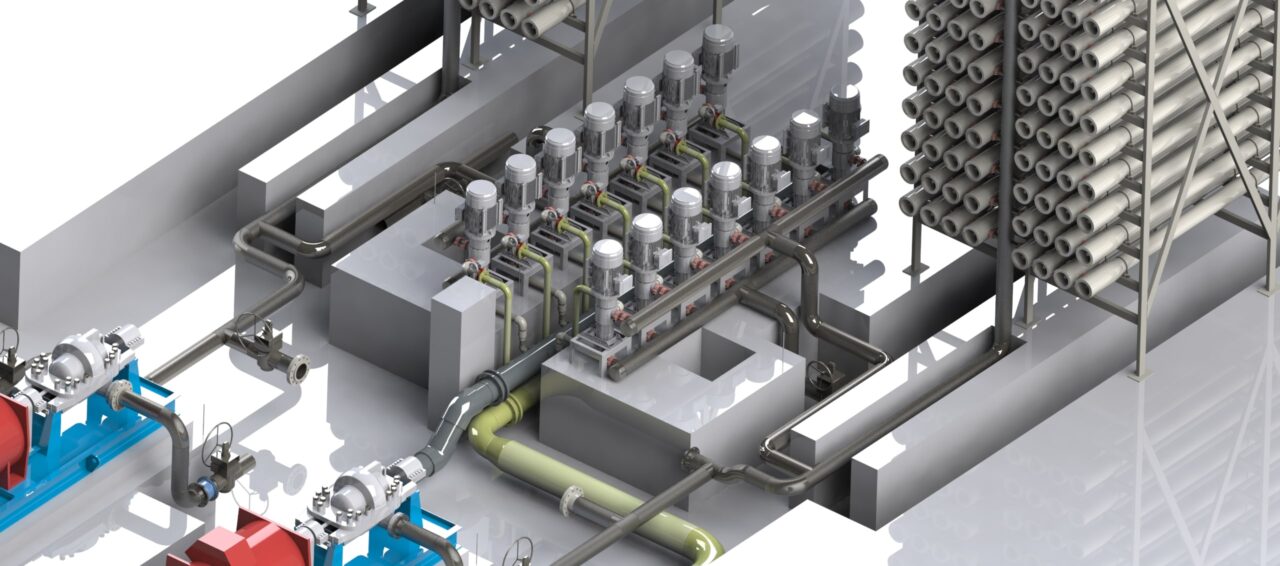

For this application, the recovery system is based on isobaric chambers that exchange pressure and brine transfer booster pumps, so that the energy recovery device transfers the pressure from the high-pressure brine stream to the low-pressure seawater stream. This pressure transfer process occurs through the momentary contact of both streams in the rotor ducts within the ERD.

In a reverse osmosis system equipped with this type of energy recovery device, the membrane reject stream is redirected to the membrane feed. The brine stream passes through the ERD, where pressure is directly transferred to the seawater with up to 98% efficiency. The pressurized seawater stream, which is almost equal to the brine stream in pressure and volume, passes through the recirculation Booster pump. The booster pump drives the water into the high-pressure circuit at a rate controlled by a frequency converter on its motor. The fully pressurized seawater is then driven from the booster pump and joins the seawater stream coming from the high-pressure pump.

IMAGES 1 to 5

Following the same operating principle as above, the DANFOSS iSAVE units operate as independent isobaric chambers, with each station having its own integrated booster pump.

This design allows for slightly broader operational versatility but comes with a more complex control architecture due to the greater number of electrical components in operation.

IMAGES 6 to 10